How to choose the best suitable UV sandblasting film (mask)?

Choosing The Right Photoresist film (type and thickness) will make sandblasting easier. Production will be faster and minimizing screw-ups. You can find more types of films in our portfolio. And each of them excels in something. Let's take a look at the main features of each UV sandblasting photoresists film below.

|

|

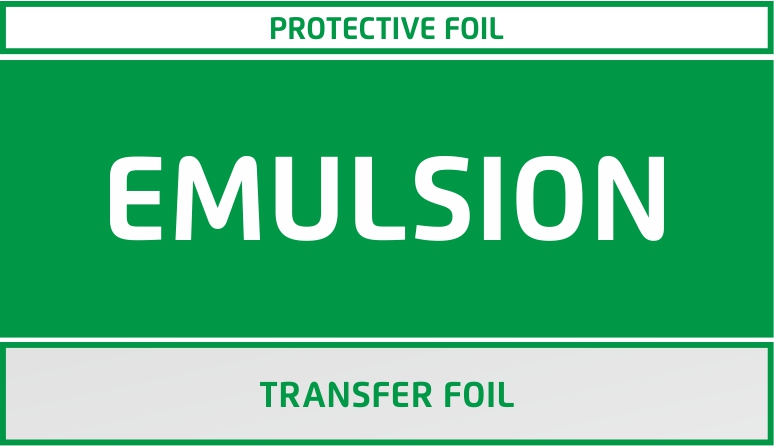

Rapid Mask 50µm (non-washable) - green

Pros:

- The process of washout and following drying is eliminated, there is no need to invest in a washout box and dryer.

- Also suitable for beginners.

- Easy application and adhesion to the item.

- It is also suitable for sandblasting detailed graphics (photographs, curves...)

Cons:

- More sensitive to light (may cause degradation). However, we can advise you on how to prevent and avoid this risk.

- In pre-print preparation, we have to keep in mind that we are preparing the logo as a negative.

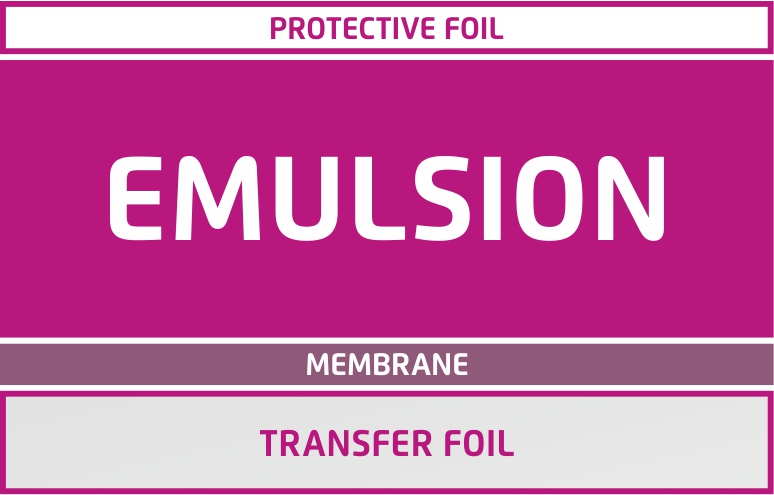

APM Plus 75µm / 125µm (washable) - purple

Pros:

- Self-adhesive and very soft, it is easy to work with.

- It is easy to remove after sandblasting.

- Very suitable for sandblasting on porcelain, in case of 125µm also for deep sandblasting.

- For the pre-print preparation we prepare the logo as a positive.

- Shorter exposure times.

Cons:

- For someone, washing and then drying.

- Higher adhesion, after sticking to the object it cannot be removed without damage.

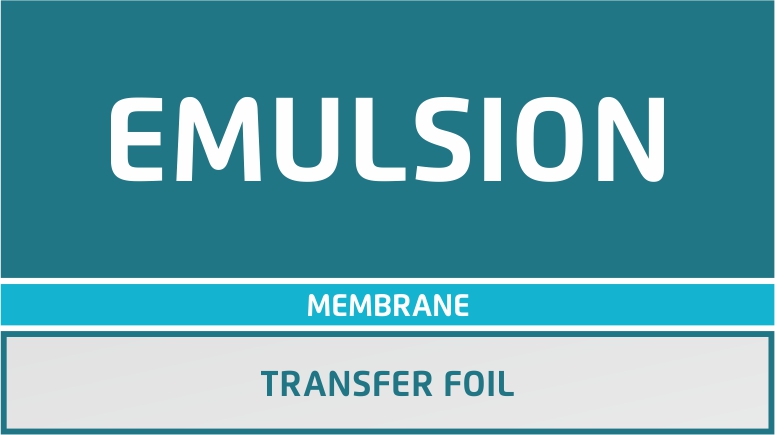

APM R3 (75µm) / R5 (125µm) (washable) - blue-green

Pros:

- Self-adhesive, however, the big advantage is that it can be removed and reapplied after wrong application on the surface.

- It is easy to remove after sandblasting.

- It is suitable for general use, on glass and porcelain.

- It washes out very well even in the case of smaller details or photographs.

- In pre-printing, we prepare the graphics as positives and therefore there is less ink consumption during printing.

- It is not sensitive to light after exposure.

- Shortest exposure times of all listed films.

Cons:

- For someone, washing and then drying.

- It requires moisture in the air for proper adhesion, in dry periods the adhesion may decrease, this problem can be corrected with humidifier.

|

|

MicroMask (washable) - light blue

Pros:

- Used for sandblasting very fine details (80 lpi raster). Halftones with a point below 0.120 mm. It is therefore also suitable for stencils with the finest details.

- It is used for both straight and rounded product shapes.

- In powerful vacuum exposure units the exposure time is 5s. In the basic model without vacuum, the exposure of this film is not recommended!

Cons:

- It is not self-adhesive, so you need to use a special external adhesive suitable for UV sandblasting stencils.

|

UltraPeel (125µm) (washable) - glossy light blue

Pros:

- Self-adhesive.

- Easy to apply to the sand blast surface - can be reapplied.

- It is resistant to solvents and thinners, so it is suitable for the technique of painting items after sandblasting.

- Used for text, curves and raster graphics (raster max. 45 lpi).

- For storing finished stencils ready for production, we recommend using a reusable silicone transfer film.

Cons:

- For someone, washing and then drying.

UltraVinyl (washable) - red

Pros:

- Durable film that can be sandblasted with coarser corundum (from fraction 60 to 150).

- It is very suitable for deep sandblasting, i.e. also for sandblasting into stone.

Cons:

- Not so good for graphics with fine details.

- For someone, washing and then drying.

From the above we can say that it mainly depends on the user's preference and the result they want to achieve.

Didn't find what you were looking for or need help with choosing the right film? Contact us or sign up for one of our sandblasting workshops.

If you have any further questions, please contact us at realizace@gds.cz or call +420 571 612 420.

The article was written by:

Ing. Klára Žilová

Sandblasting stencils, Custom sandblasting, Customer service

Coloured Glass Enamel Colour Paint

We are traditional producer of Ceramic Enamel Paints for toughened glass. More than 20 years experience with tinting process.

more information

Available RAL and NCS shades

Note of RAL and NCS available shades of Ceramic colors for Flat Glass.

more information